We’re all familiar with cannabis consumption to some degree. Even if you have not consumed it personally, it is likely that you know someone who has, and you have a basic understanding of how it works. When customers shop for cannabis, it’s unlikely that they put a lot of thought into where it came from. Often, people do not even realize that every specific product on our shelves was grown, produced, trimmed, extracted, and packaged all in our own facility.

Aloha Green—and cannabis dispensaries on the islands of Hawaii in general—are completely different than dispensaries on the mainland. If you’ve ever shopped recreationally or even medically on the mainland, maybe you noticed the variety of different brands on their shelves. Some people don’t even think about this when shopping, or maybe they just assume that the dispensary produced all of those products. But they likely came from several different companies. The majority of mainland dispensaries have 3rd-party vendors who sell their brands through the dispensary. This means that without the dispensaries, those companies would not have a place to sell their products. Even if a dispensary on the mainland has its own grow facility and produces its own flower, it is unlikely that they also produce the other products (tinctures, edibles, oils, etc.) because these typically come from third-party companies in the industry.

When you shop with Aloha Green, every product is Aloha Green. We do not have third-party companies or vendors. From seed to fully bloomed plants, plants to oils, oils to vapes… it all starts on the Aloha Green farm! In cannabis, we call this being “vertically integrated.”

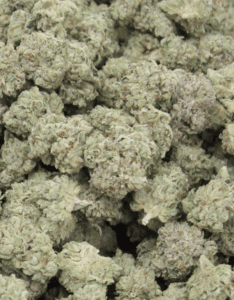

Our farm facility has many moving parts, each just as important and crucial to the production of products as the other. Each plant goes through several stages before it ends up in a container in your shopping bag. That flower you’re smoking, the tinctures you’re dropping under your tongue, and the soft chews you eat—all went through a vigorous process to end up in your hands.

Growing cannabis is an extremely tedious and thoughtful job. Cannabis plants require specific care, nutrients, lighting, and watering, and neglecting a plant in any aspect can cause it to quickly die or become unhealthy. On Aloha Green’s farm, there are many behind-the-scenes team members who make sure each plant is healthy from the planting of the seed to being placed in a package. Planting, cloning, potting/repotting, watering, making nutrients, spraying, trimming, curing, extracting, packaging, and labeling… and then delivering the products to each of our store locations. Cannabis plants require a lot of attention. It’s pretty much impossible—with the amount of plants growing on our farm—to have 1-2 people doing everything. The entire process literally takes an army. While one person is watering, someone else is trimming, and so on. Each department is constantly working their role for their entire work shift. The carousel never stops turning on the farm!

Extracting oil and terpenes from the plants happens in our lab, where tinctures, cartridges, and other THC-infused products are made. The significance of this is that… it’s so rare that a dispensary is vertically integrated like this and handles everything from plant growth to the production of vape products and massage oils. At Aloha Green, we really do care about what our community is consuming. Producing our own products means we know exactly what ingredients are in it. We know exactly what tests that product went through before it ended up in your hands. We know each product like the back of our hand because we started it from scratch, and this is what makes us different from a dispensary that is not vertically integrated. There’s no disconnect between us and the product we are selling you!